Rain Gauge: Exploring the Design and Sustainability of 3D Printed Clay Physicalizations

Bridger Herman - University of Minnesota, Minneapolis, United States

Jessica Rossi-Mastracci - University of Minnesota, Minneapolis, United States

Heather Willy - University of Minnesota, Minneapolis, United States

Molly Reichert - University of Minnesota, Minneapolis, United States

Daniel F. Keefe - University of Minnesota, Minneapolis, United States

Screen-reader Accessible PDF

Download preprint PDF

Room: Esplanade Suites I + II + III

2024-10-14T16:00:00ZGMT-0600Change your timezone on the schedule page

2024-10-14T16:00:00Z

Abstract

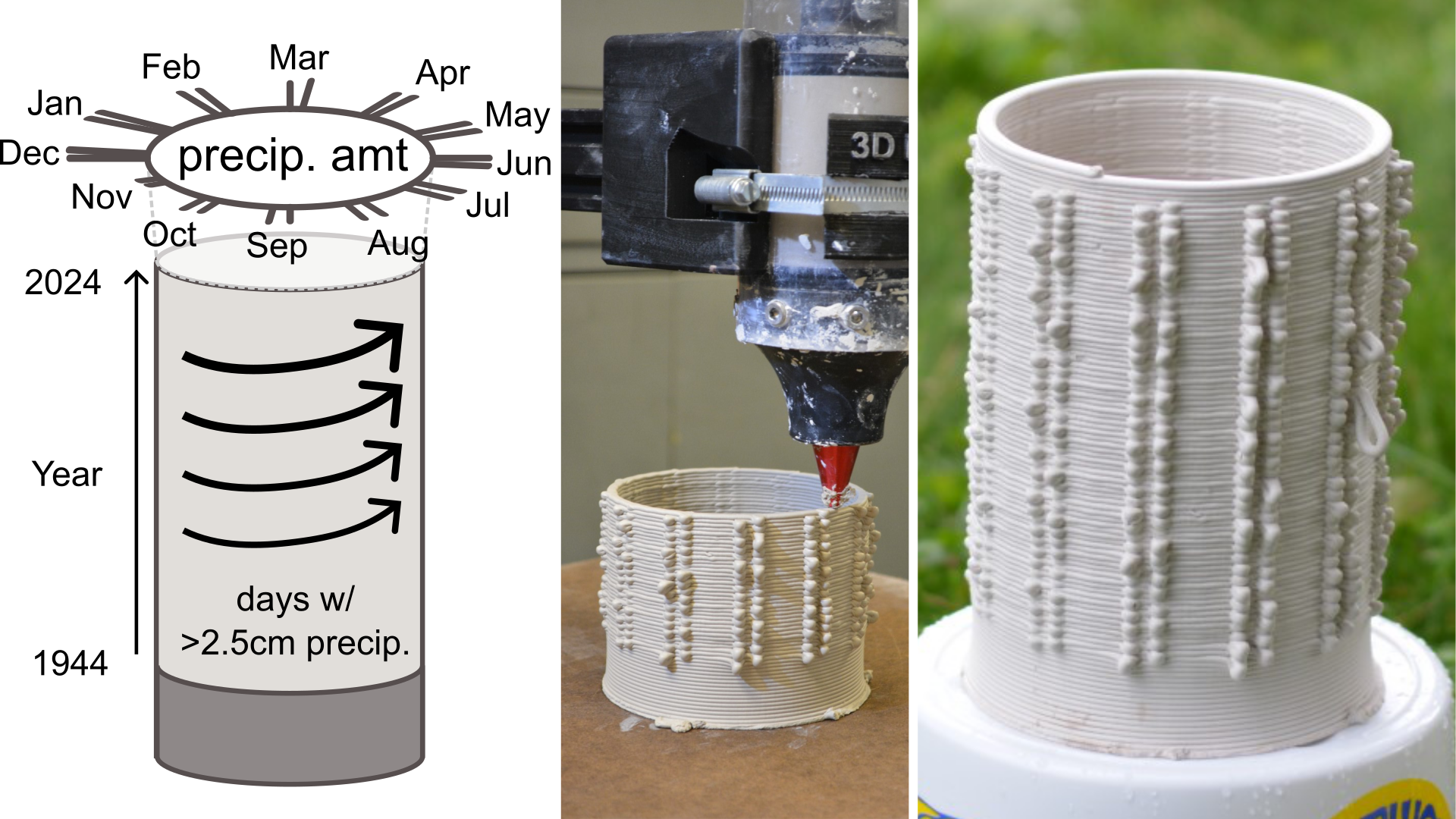

Data physicalizations are a time-tested practice for visualizing data, but the sustainability challenges of current physicalization practices have only recently been explored; for example, the usage of carbon-intensive, non-renewable materials like plastic and metal.This work explores clay physicalizations as an approach to these challenges. Using a three-stage process, we investigate the design and sustainability of clay 3D printed physicalizations: 1) exploring the properties and constraints of clay when extruded through a 3D printer, 2) testing a variety of data encodings that work within the constraints, and 3) introducing Rain Gauge, a clay physicalization exploring climate effects on climate data with an impermanent material. Throughout our process, we investigate the material circularity of clay-based digital fabrication by reclaiming and reusing the clay stock in each stage. Finally, we reflect on the implications of ceramic 3D printing for data physicalization through the lenses of practicality and sustainability.